Search

Popular Searches

Search Via

Product Application

Search

Popular searches

Search via

DISCOVER ZIP‑CLIP SOLUTIONS

Product Application

About … WHY?

WHY USE WIRE?

A Proven Concept …

Early in the nineteenth century, visionary engineers discovered that when steel is drawn into wires its strength increases, meaning a flexible wrap of steel wires is stronger than a solid steel bar of the same diameter, thereby offering higher load capacity with considerably less material.

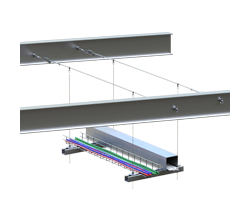

Zip-Clip Wire Suspension and Bracing Systems

The wire used in all Zip-Clip systems is a premium product with a tensile strength of 1960 N/mm². It is available in load ranges from 15 kg to 500 kg with all solutions designed to include a built-in safety factor.

This level of performance and accountability provides the confidence to use Zip-Clip wire in place of traditional threaded rod or chain-supported suspensions and is one of the principal reasons why today wire rope is being specified for an ever-increasing range of applications.

Wire rope systems offer increased installation flexibility and speed, reduced materials requirements and waste, and provide the installer with a suspension solution that helps meet the latest environmental needs of projects.