Fire Strut-Lock

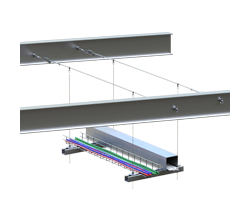

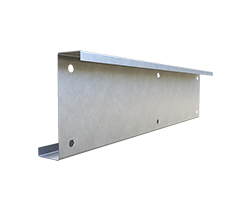

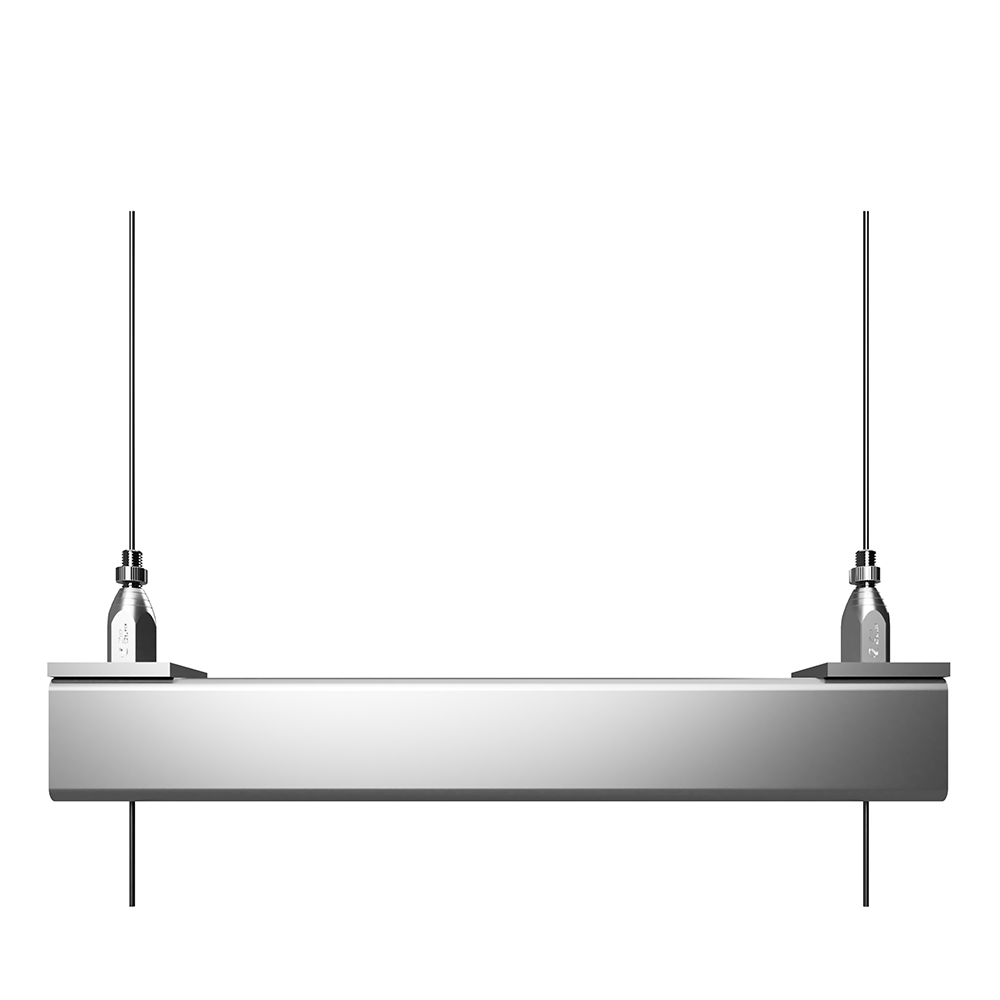

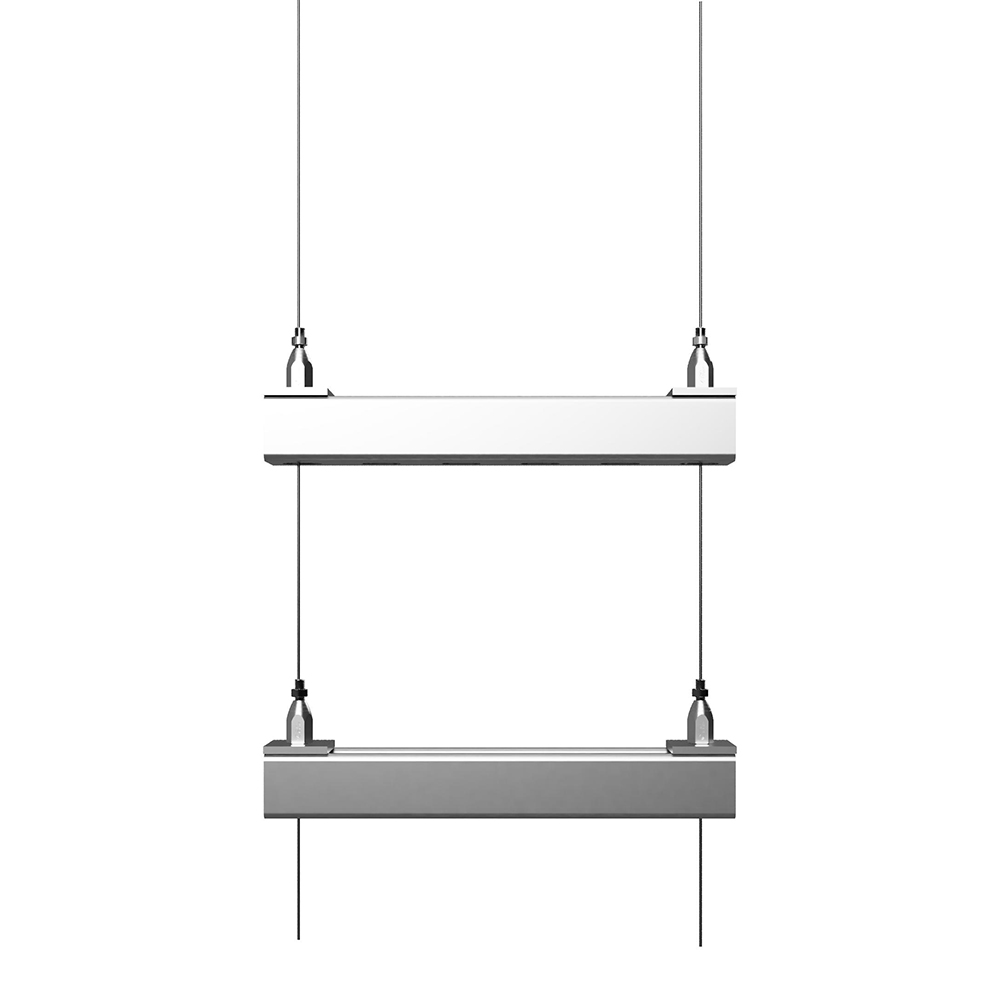

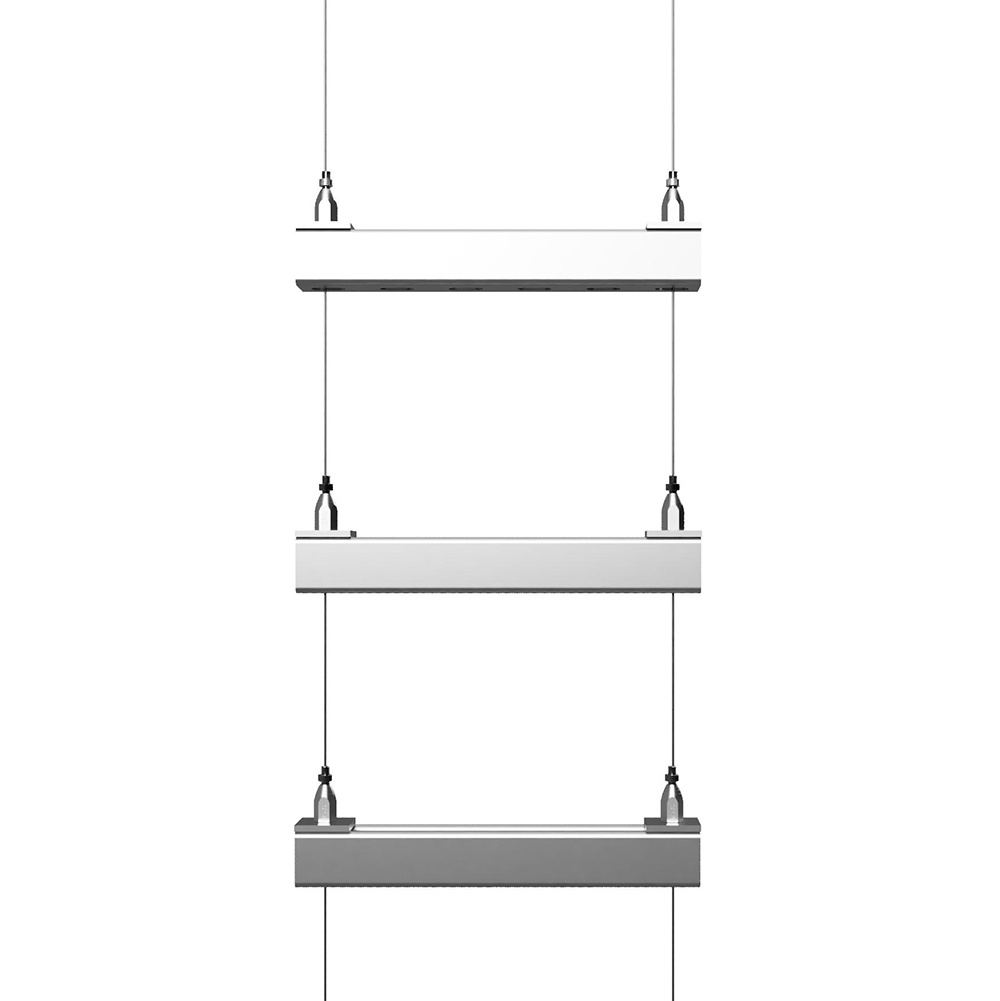

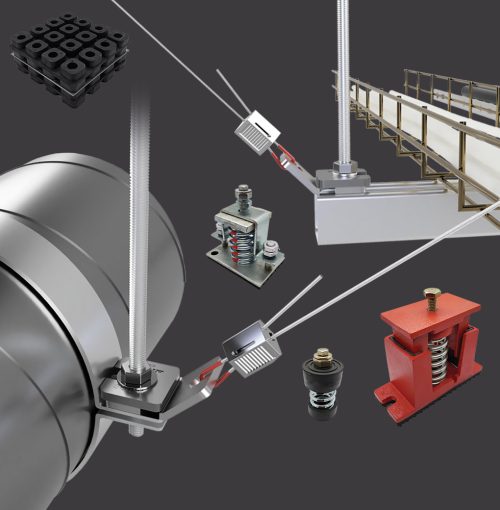

THE FIRE STRUT-LOCK SYSTEM utilises stainless steel wire rope to offer optimum performance in fire environments. The system can be used to construct lockable single or multi-tiered trapeze bracketry.

THE APPLICATIONS

SUITABLE AREAS OF USE INCLUDE, BUT ARE NOT LIMITED TO:

- Installations to Edition 18 of the electrical wiring regulations.

- Single-tier and multi-tier trapeze brackets.

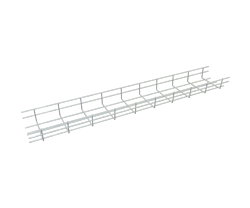

- Electrical and mechanical containment suspension.

- HVAC installations/ductwork suspension.

- Signage and displays.

- Installations above fire escape routes.

AVAILABILITY

The Fire Strut-Lock system comprises a predetermined length of stainless steel wire from 1 m to 10 m, with a Safe Working Load of 90 kg per wire suspension in ambient conditions, and is supplied with the required Zip-Clip locking device. The system offers a choice of either pressed eyelet or pressed M8 × 35 male thread termination.

Note: Fire Strut-Lock is to be used only for static loads that are supported vertically. Always ensure the base material or anchor point are suitable to support the intended load.

Safe Working Loads

- Y 90 kg