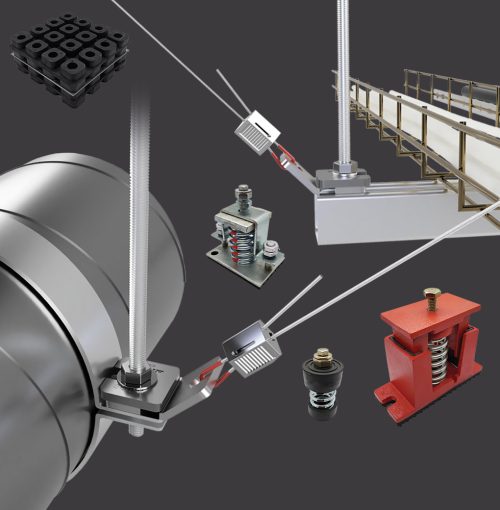

Shot-Lock

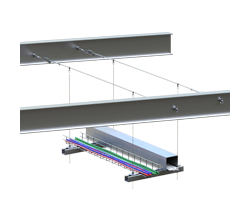

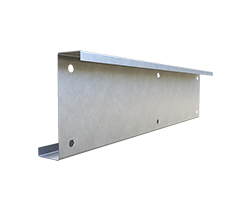

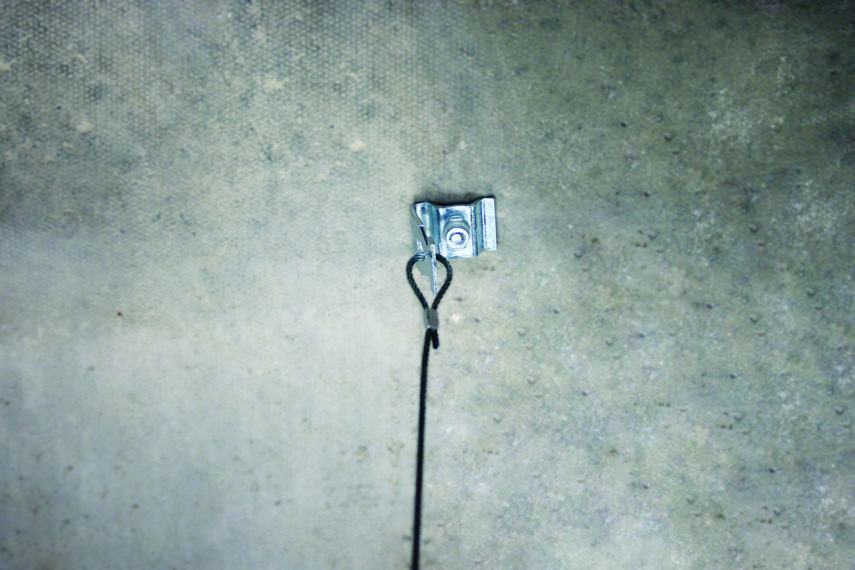

THE SHOT-LOCK SYSTEM is designed to fix a wire suspension to a base material using Powder Actuated Tools (PAT). The system comprises a predetermined length of a specific diameter wire rope with a shot-fire bracket termination (nail included) and is supplied with the required Zip-Clip locking device.

THE APPLICATIONS

SUITABLE AREAS OF USE INCLUDE, BUT ARE NOT LIMITED TO:

- Electrical containment

- HVAC and mechanical services

- Lighting and audio as primary or secondary support

- Signage and display, screens and partitions

- Acoustic ceilings, islands, or baffles

- Radiant heat panels

AVAILABILITY

Shot-Lock should be used for lightweight applications only.

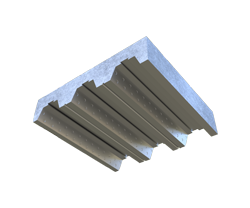

Zip-Clip offers two different Shot-Lock systems each allocated a letter to differentiate between the available safe working loads (SWL).

Shot-Lock systems are available in drop lengths of 1 m to 10 m. Loads indicated are per individual wire support when coupled with the appropriate Zip-Clip locking device.

Safe working loads

- G 15 kg

- S 25 kg