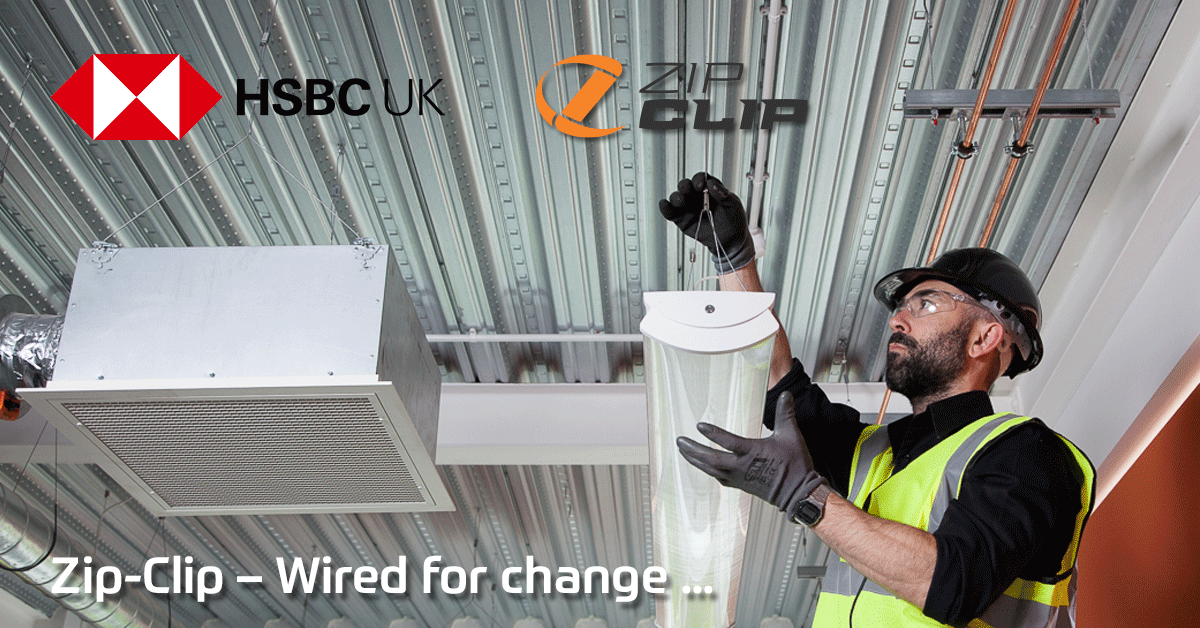

Wire suspension specialists Zip-Clip used the disruption of lockdown to launch the business to new heights

Zip-Clip had already successfully weathered one recession in its 16-year history. But that template was no help to the Powys-based manufacturer when Covid-19 struck.

“Like most businesses in March 2020, we were debating whether we should just close,” said business founder, Matthew Clay-Michael. “In a recession, you can still plan a bit – but this was totally unknown. We put a lot of staff on furlough and cut production by 60%.”

Then an unexpected letter arrived from a long-standing customer, a major electrical contractor. The firm had secured contracts to supply items to fit out several of the new Nightingale Hospitals being set up to cater for an anticipated influx of virus patients.

The client had been asked by the government to remain operational as an essential supplier to the public sector. In turn, it needed specialists such as Zip-Clip to commit to playing an active part in its supply chain.

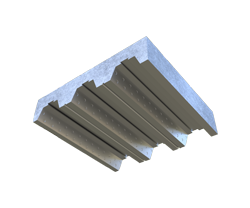

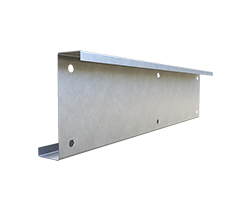

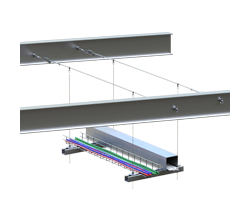

Swifter and simpler to assemble than traditional suspension systems, Zip-Clip’s wire-based solutions were seen as perfect for installing heating, ventilation, air-conditioning, electrical and other services in the new wards.

The firm’s operations were rapidly ramped up again to handle these urgent requirements. Staffing was a challenge at first, as the furlough scheme prevented immediate return for the employees affected. Matthew and CEO Steve Goldsworthy found themselves back on the shop-floor to help out.

“An order process generally goes through five or six people, from picking to dispatch” Matthew explains. “While I was handling all these processes I think I must have covered five or six miles a day around the factory!”

– – –

OPERATIONAL RETHINK

This return to the coalface had positive benefits. Like all business leaders, Matthew and Steve had inevitably become slightly detached from hands-on processes as Zip-Clip grew.

“We’re now taking a fresh look, noticing where tasks are being replicated, and finding leaner ways to do things,” says Matthew.

Lockdown also offered the perfect opportunity to tackle a long-standing ambition – changing the production shift pattern.

“It had always been hard to find skilled staff to work the unsocial hours of our 4pm to midnight shift,” Matthew explains. “But we never had time to switch off the system and start again.

“Now staff are doing the new shifts on alternate weeks: 6 am to 2 pm, and 2 pm to 10 pm. With added machinery, we’re even recruiting new production staff, ready for the next phase of growth.”

– – –

OVERSEAS STIMULUS

While the UK economy languished in lockdown, new enquiries and orders continued to flow from other territories. These helped the company maintain production at full pace even after the Nightingale orders were fulfilled.

This was especially true of Australia, where Zip-Clip has had a presence for the past two years. The Australian construction industry revived after a shutdown of just a fortnight.

This benefit of geographical diversification has convinced the firm to redouble its international efforts. It already exports to over 30 countries, and earned a Queen’s Award for Enterprise in international trade in 2019.

Currently 40% of its business is overseas; Matthew now wants to boost that to 60%. Japan and India being key targets.

“This has made us look more aggressively at employing people overseas, which we’ve sometimes been reluctant to do,” he says.

“While we’ll maintain our UK staff at current levels, we’ll be channelling some of our UK budget to our overseas efforts. In preparation, we’ve already begun to invest in in-house expertise in international HR and employment law.”

– – –

DIGITAL DRIVE

The lockdown experience proved the merits of Zip-Clip’s recent shift to remote finance and email systems that can be accessed by staff from any location. His review of the business has convinced Matthew that the firm’s digital strategy needs to be accelerated.

“Rather than replacing old equipment on a like-for-like basis, we’re now looking at how we can introduce more robotics,” says Matthew. His ambition is to invest heavily in digital solutions over the next three years.

One element of Zip-Clip’s business will definitely not change, however. It has spent 18 months developing a trade line system with overseas suppliers.

HSBC’s backing via a £1m global trade facility gives suppliers the confidence to provide major orders of six months’ worth of raw materials. This was what enabled Zip-Clip to fulfill the urgent Covid-related contracts without delay.

“Even though there were shutdowns at some of our supply factories, we had plentiful stock to support all our customers,” Matthew says. “Covid was an extreme stress test of that system, and it came through.”

– – –

CONFIDENCE RETURNS

Like most companies, Zip-Clip took an income hit at the onset of the pandemic. However, Matthew was confident that the business would be back on track by the yearend, maintaining its £6m turnover.

He sees similar optimism in other businesses. “Lockdown has given people an odd opportunity: to have a break and introduce changes within the organisation that will create further growth in the long run,” he concludes.

– – –

If you require any further information, or if Zip-Clip can be of any assistance to you, please do not hesitate to get in touch with your usual point of contact or contact our head office on +44 (0)1686 623366, email info@zip-clip.com.

– – –

Article reproduced with permission of HSBC UK, July 2020.