Seismic Bracing

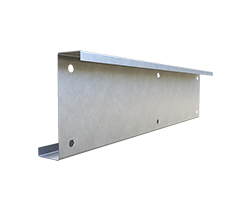

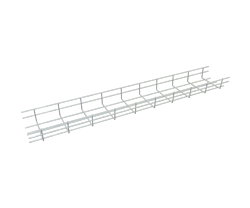

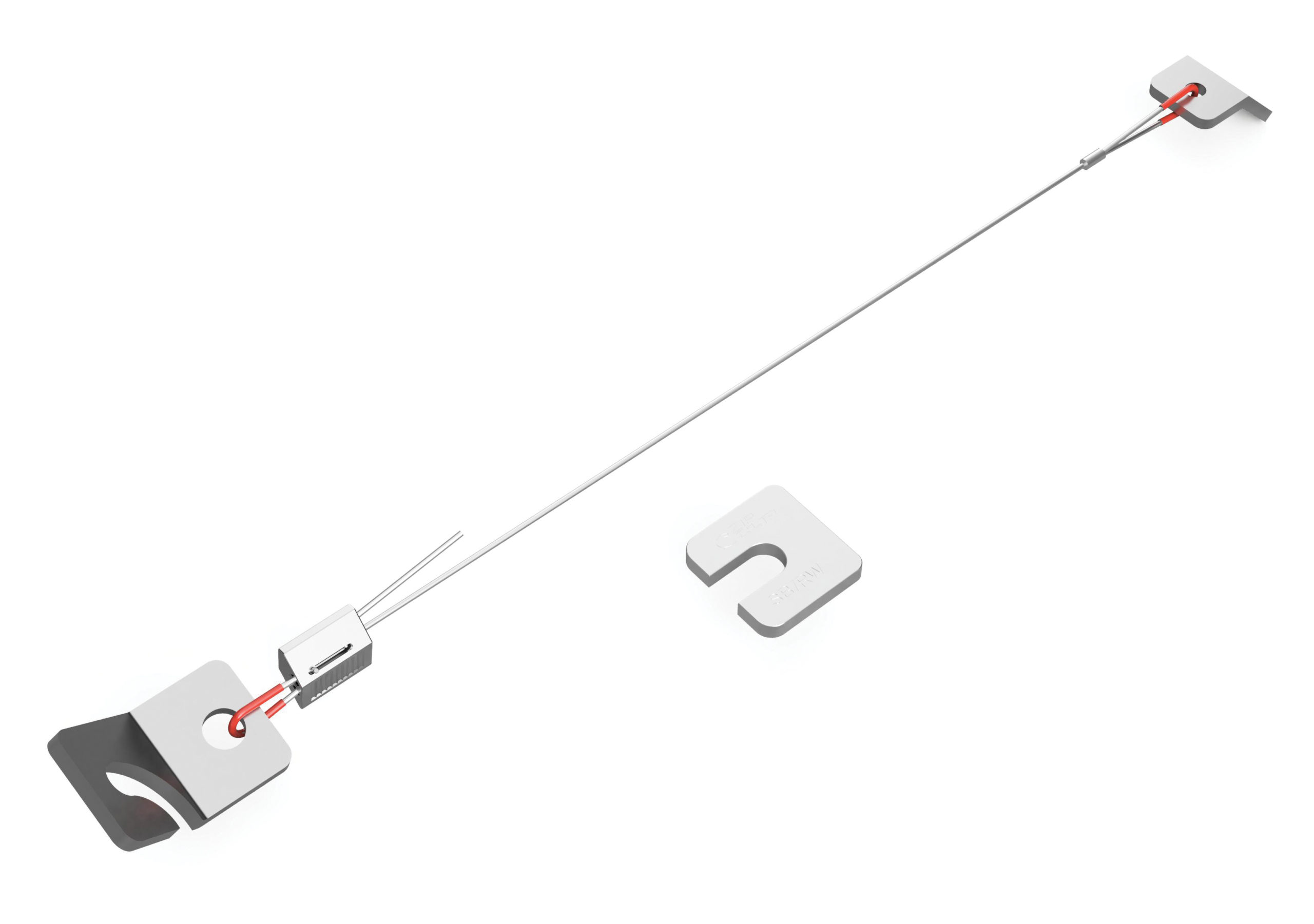

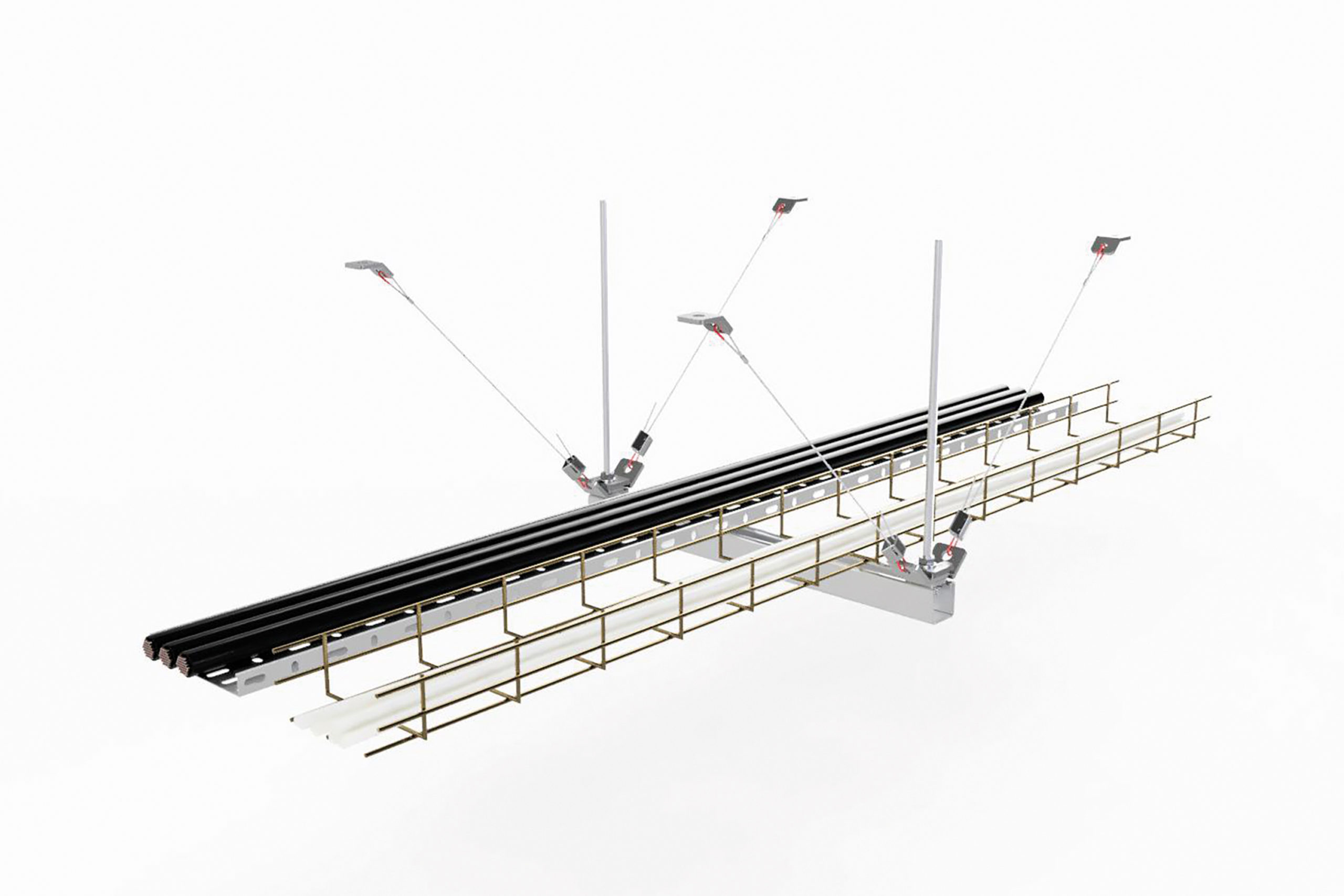

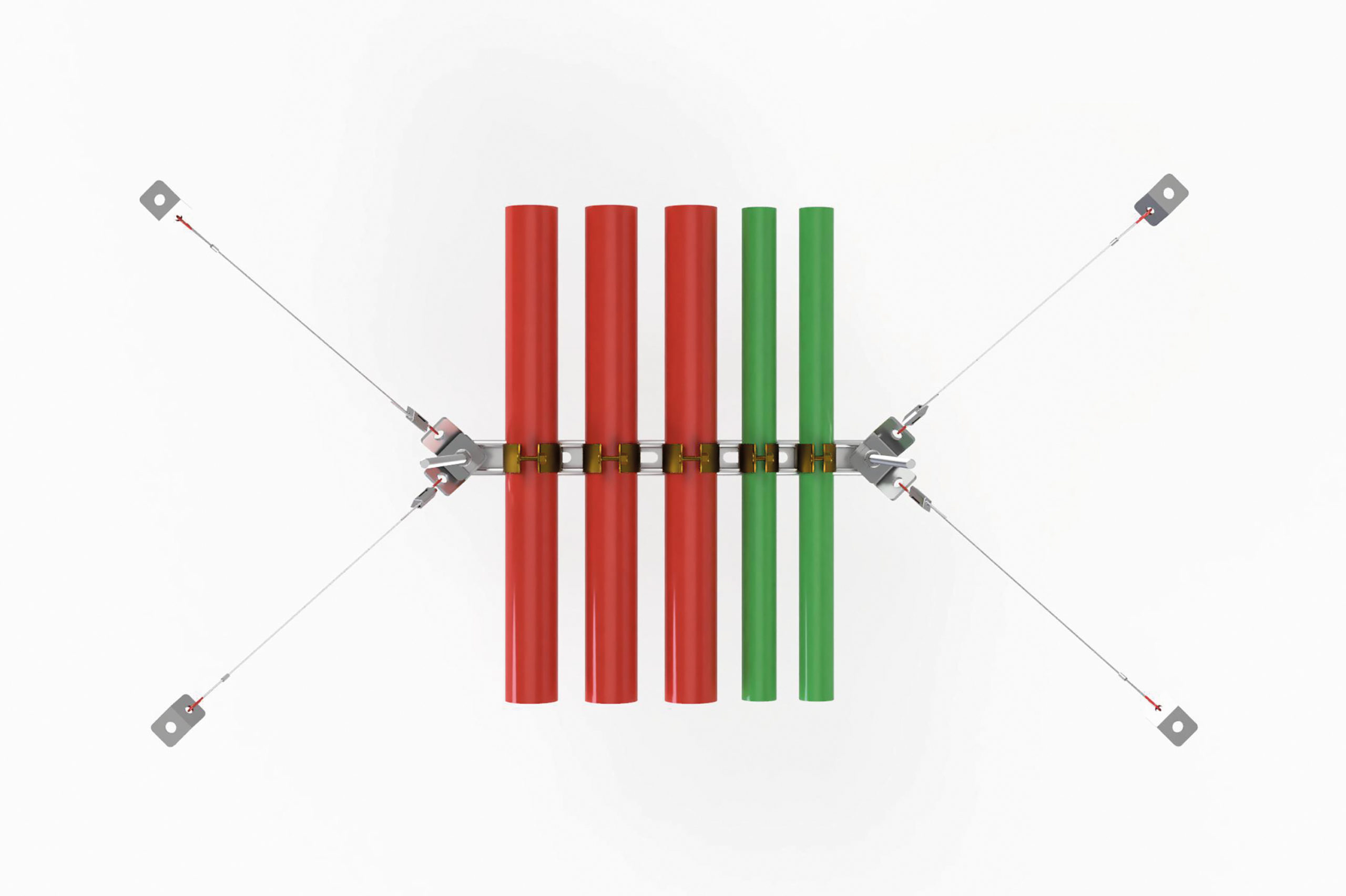

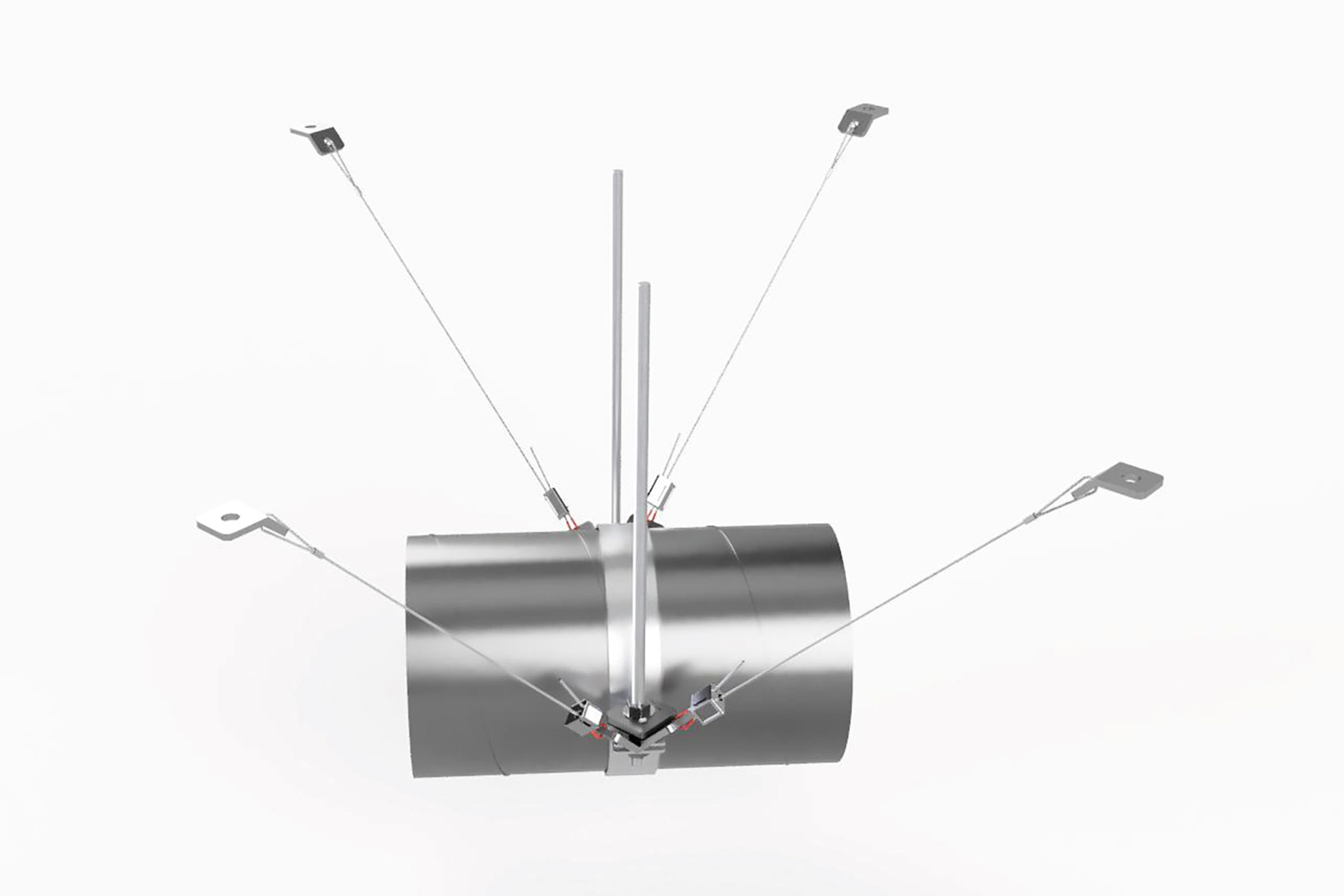

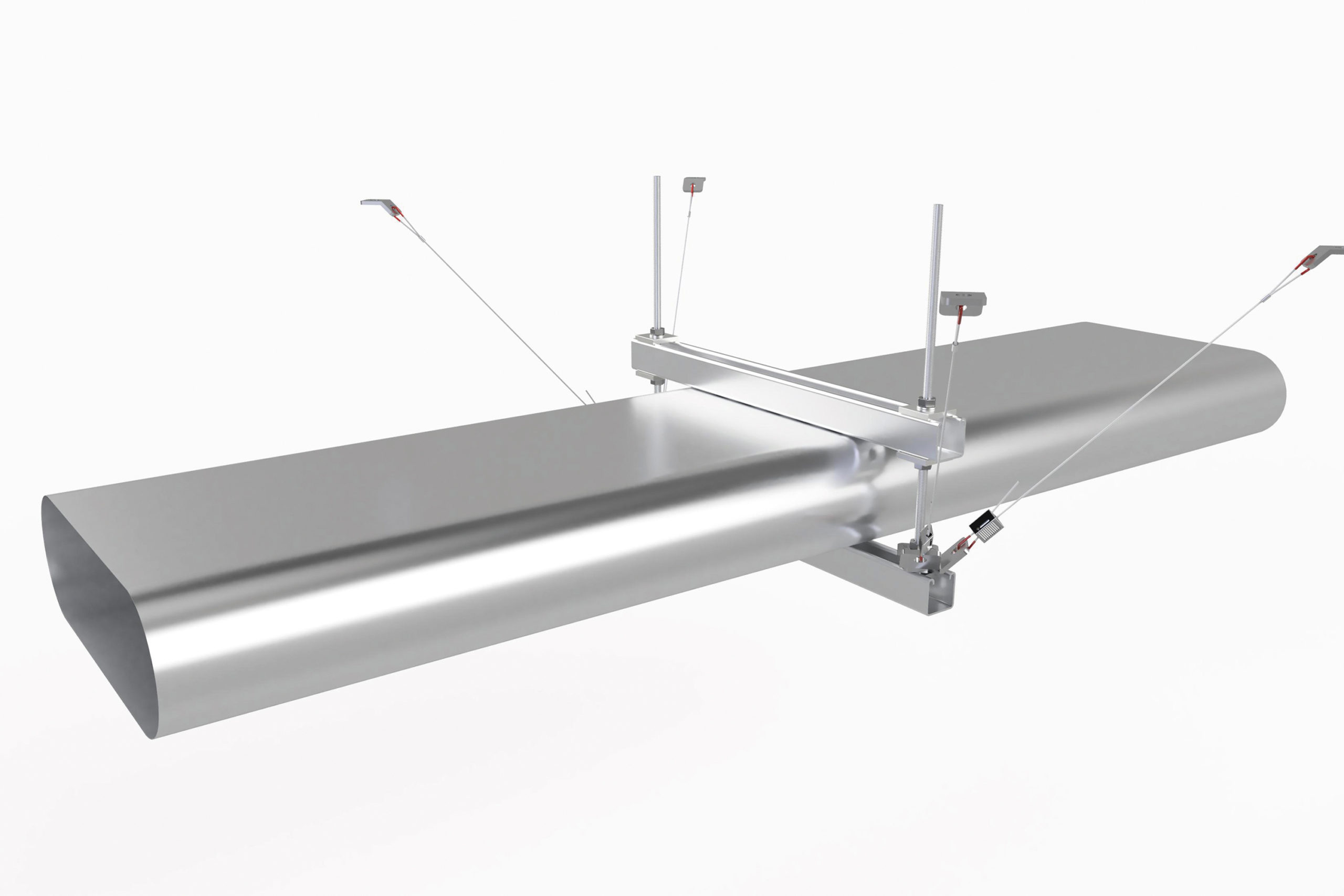

Solutions for Building Services

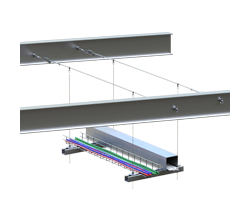

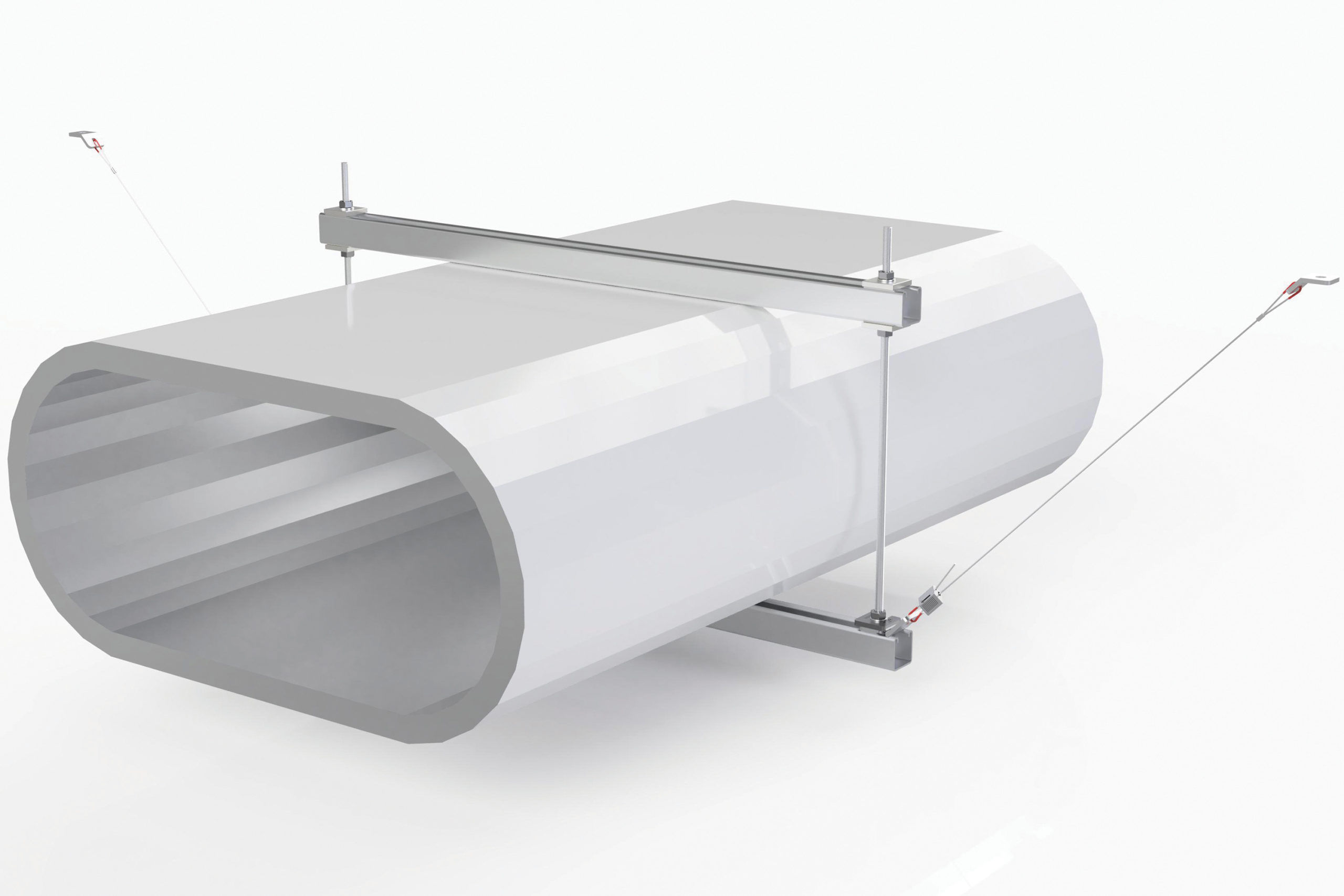

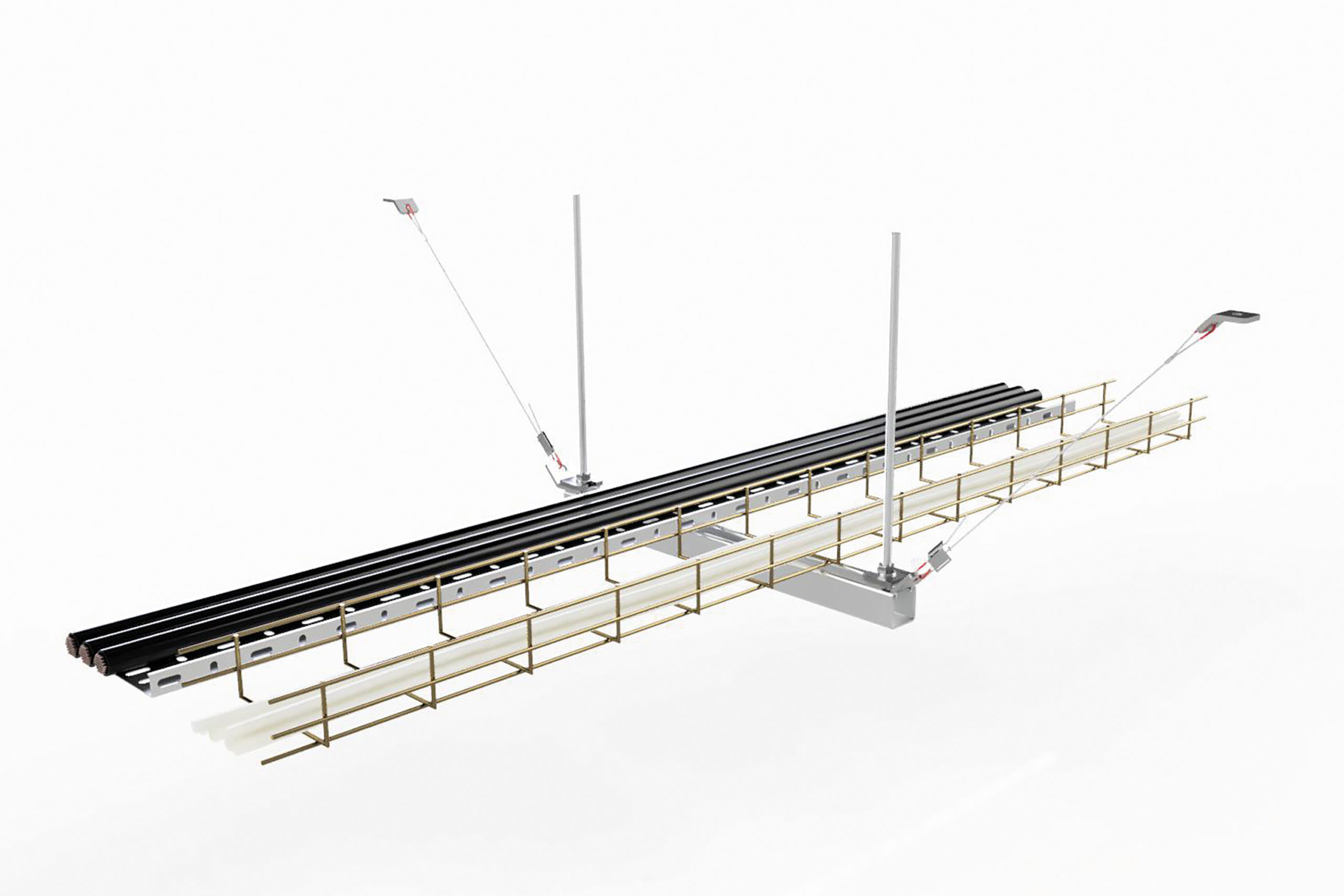

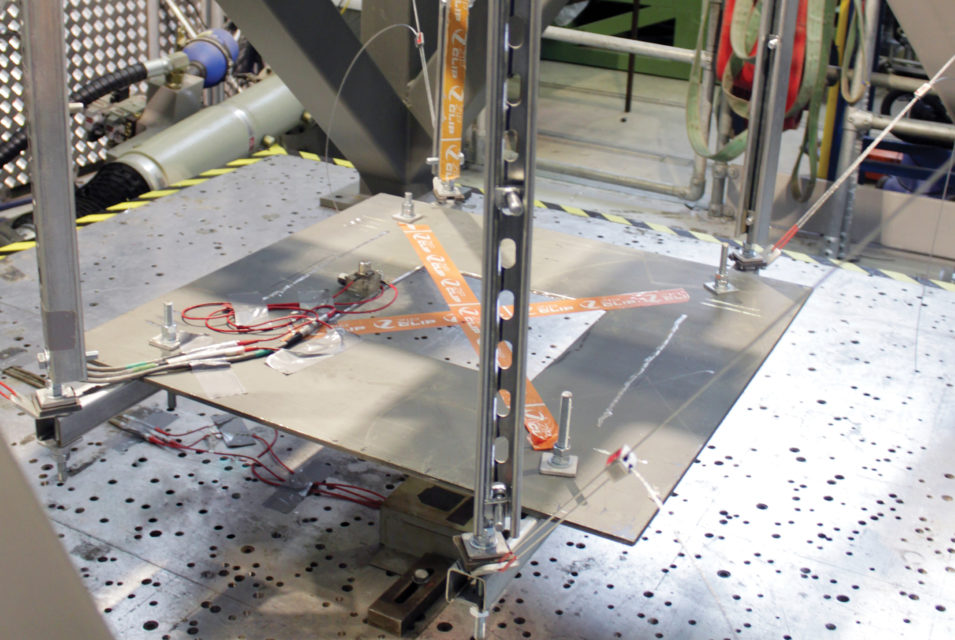

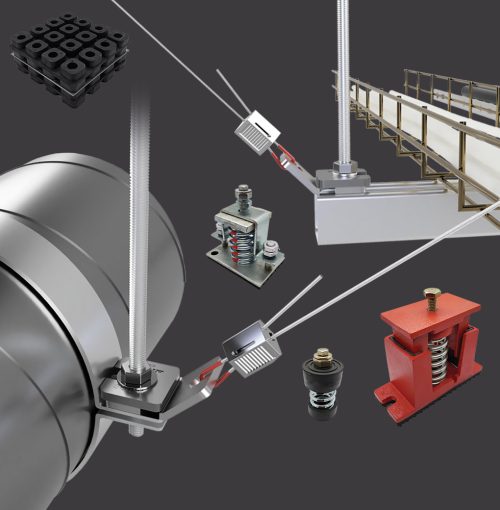

Zip-Clip Seismic Bracing Systems offer a simple and engineered solution to brace and secure non-structural building services, improving the resilience and safety of buildings in the event of an earthquake. This website provides an overview of the bracing systems available. Also available, on request, is a specific design manual that provides Structural Engineers and Contractors with a more in-depth overview of typical seismic design requirements for non-structural services and demonstrates the functionality and capacity of Zip-Clip seismic bracing systems.

Earthquakes are the natural result of our planet’s continually moving outer crust and have the potential to cause significant damage to buildings and harm or loss of life to occupants. While they occur more frequently in certain regions, earthquakes can and do occur everywhere on the planet.

In consideration of this natural hazard, modern building codes require that buildings are designed and built with some level of resistance to earthquakes. For most buildings, these requirements have typically focussed on ensuring that occupants aren’t injured and can safely evacuate a building following an earthquake. Recent experiences, however, have widely demonstrated that when earthquakes do occur this ‘life-safety’ level of seismic performance can result in a large amount of non-structural damage and disruption, and unrepairable building structures which ultimately need to be demolished.

Critical buildings like hospitals are typically designed to remain fully operational following an earthquake up to a certain design magnitude, and there is growing consensus that less important buildings should also be designed to be repairable, within reasonable time frames and costs.

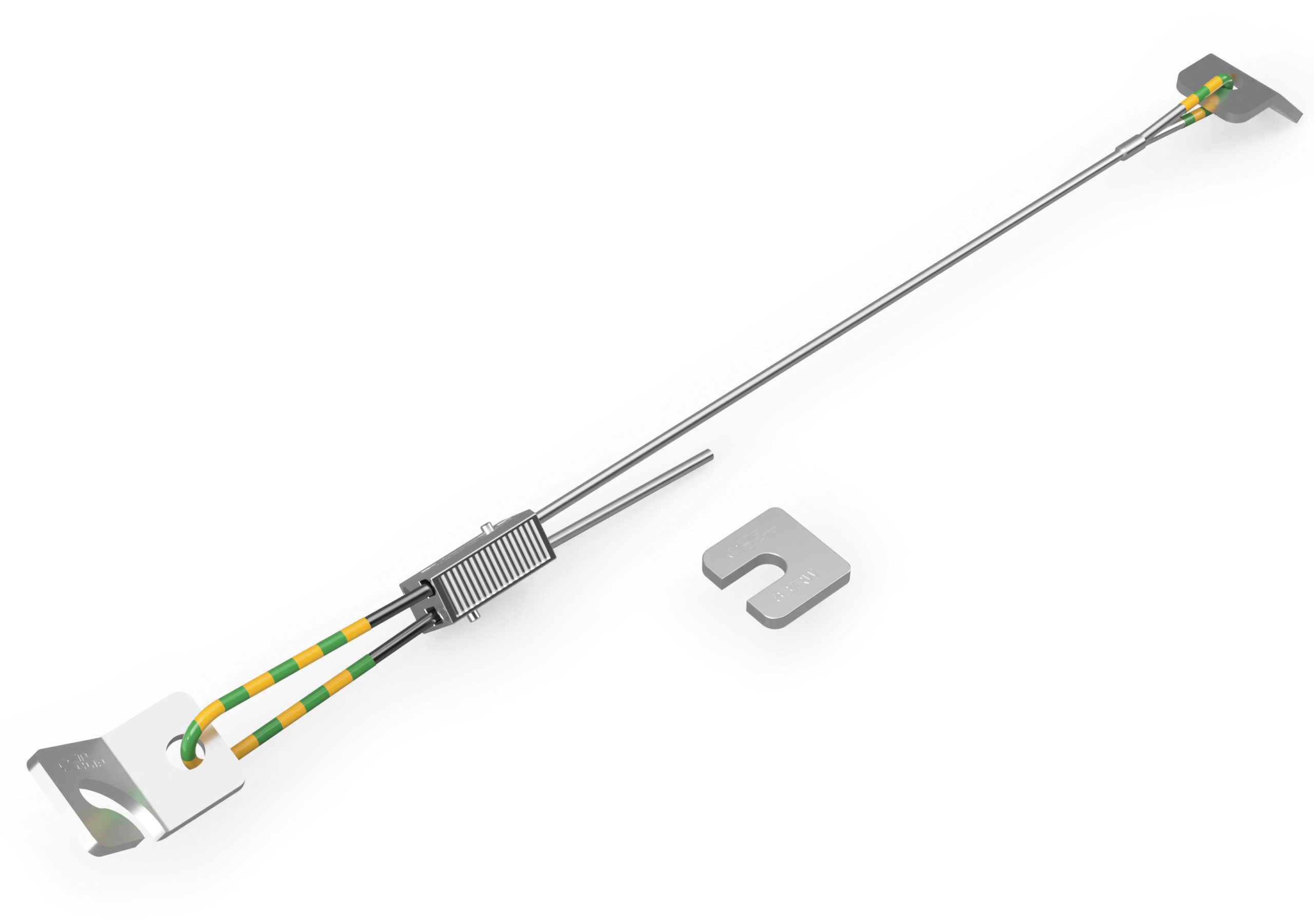

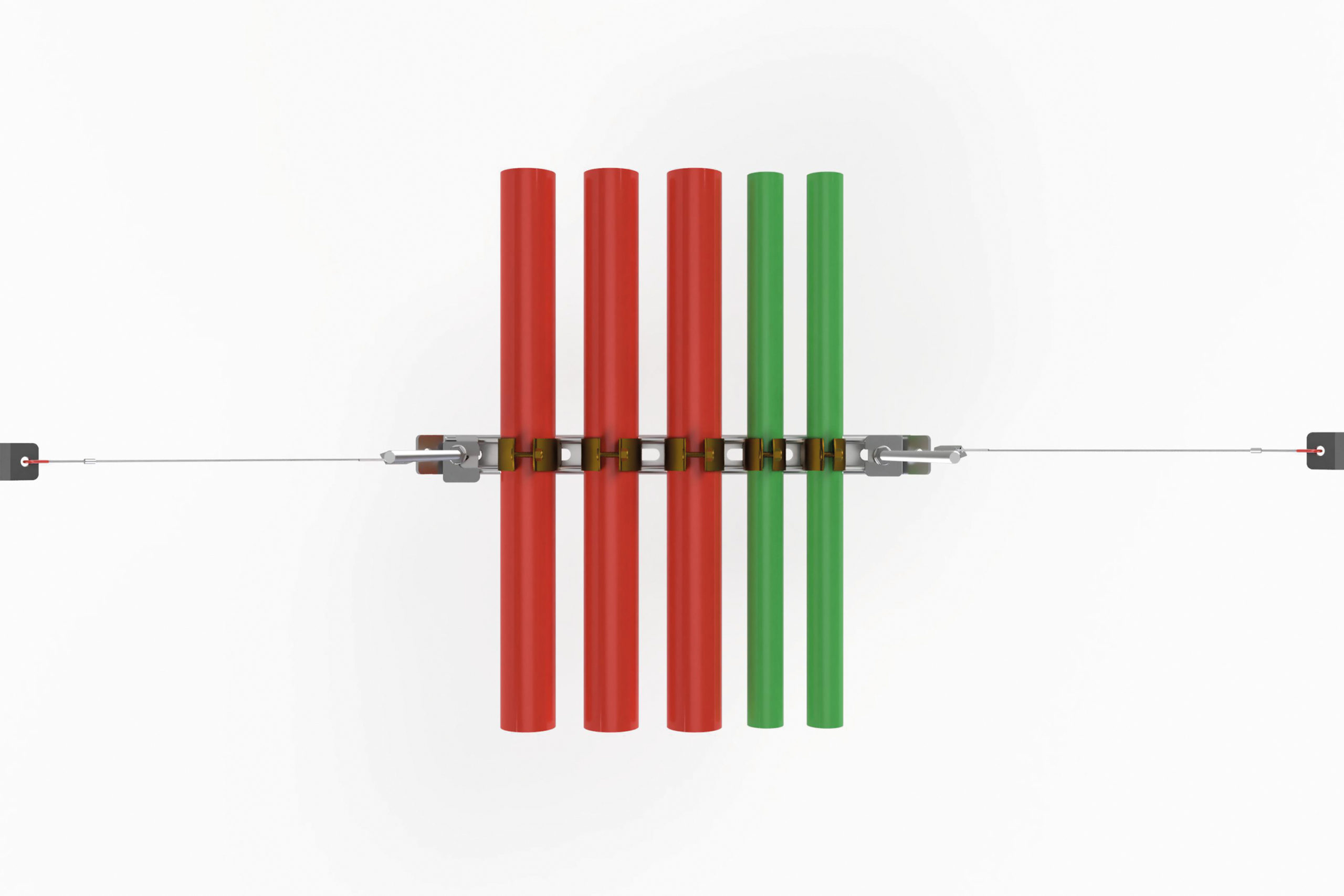

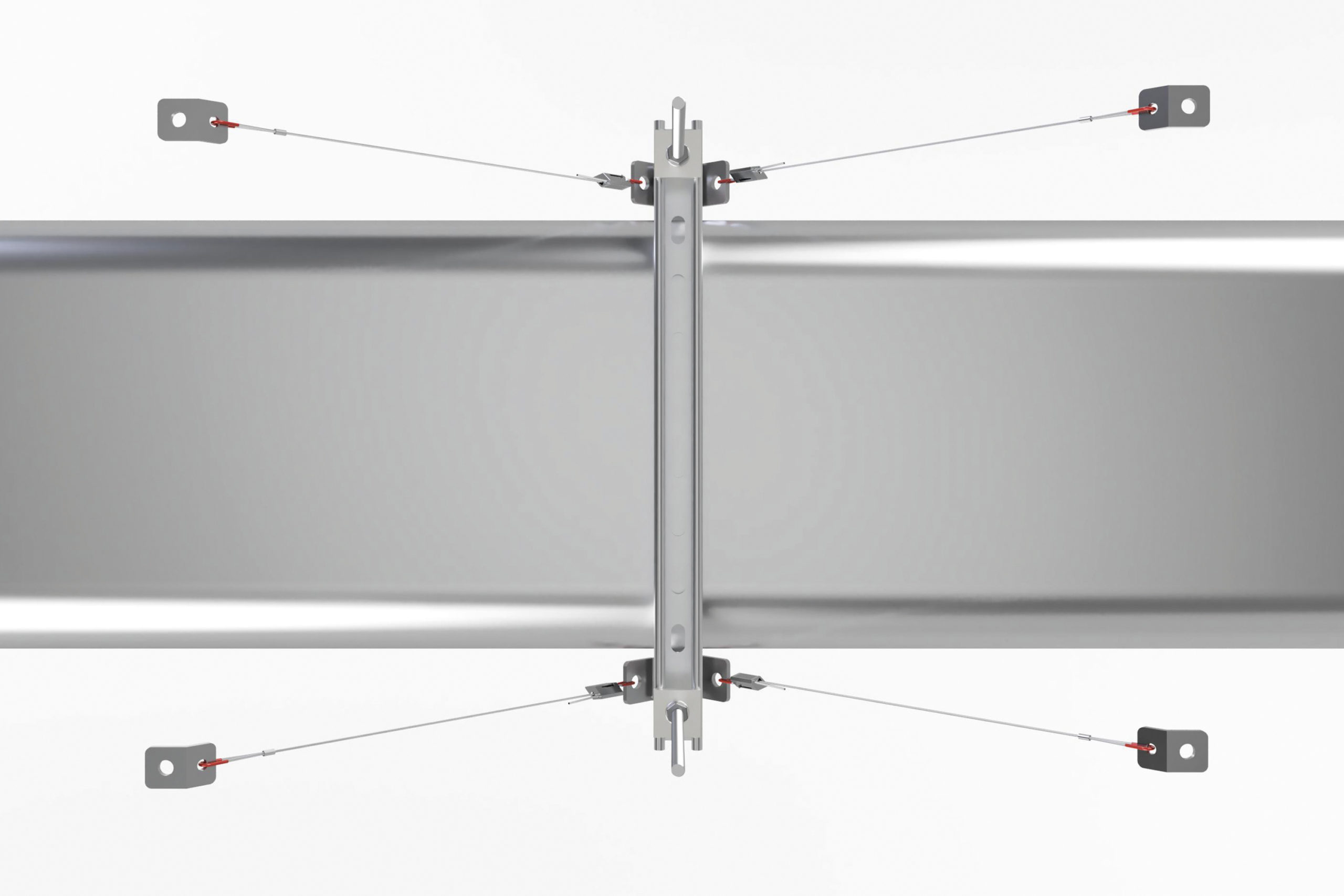

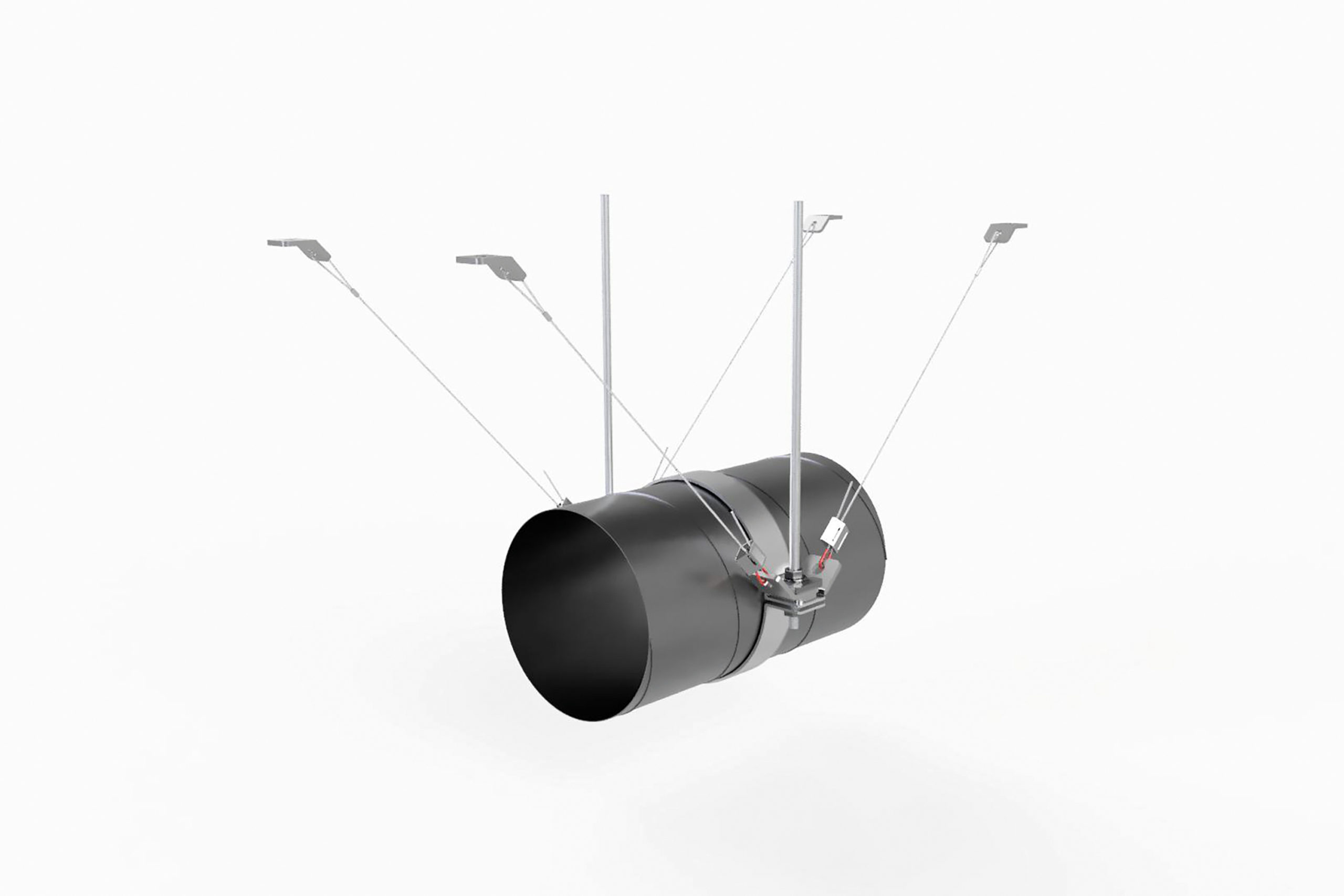

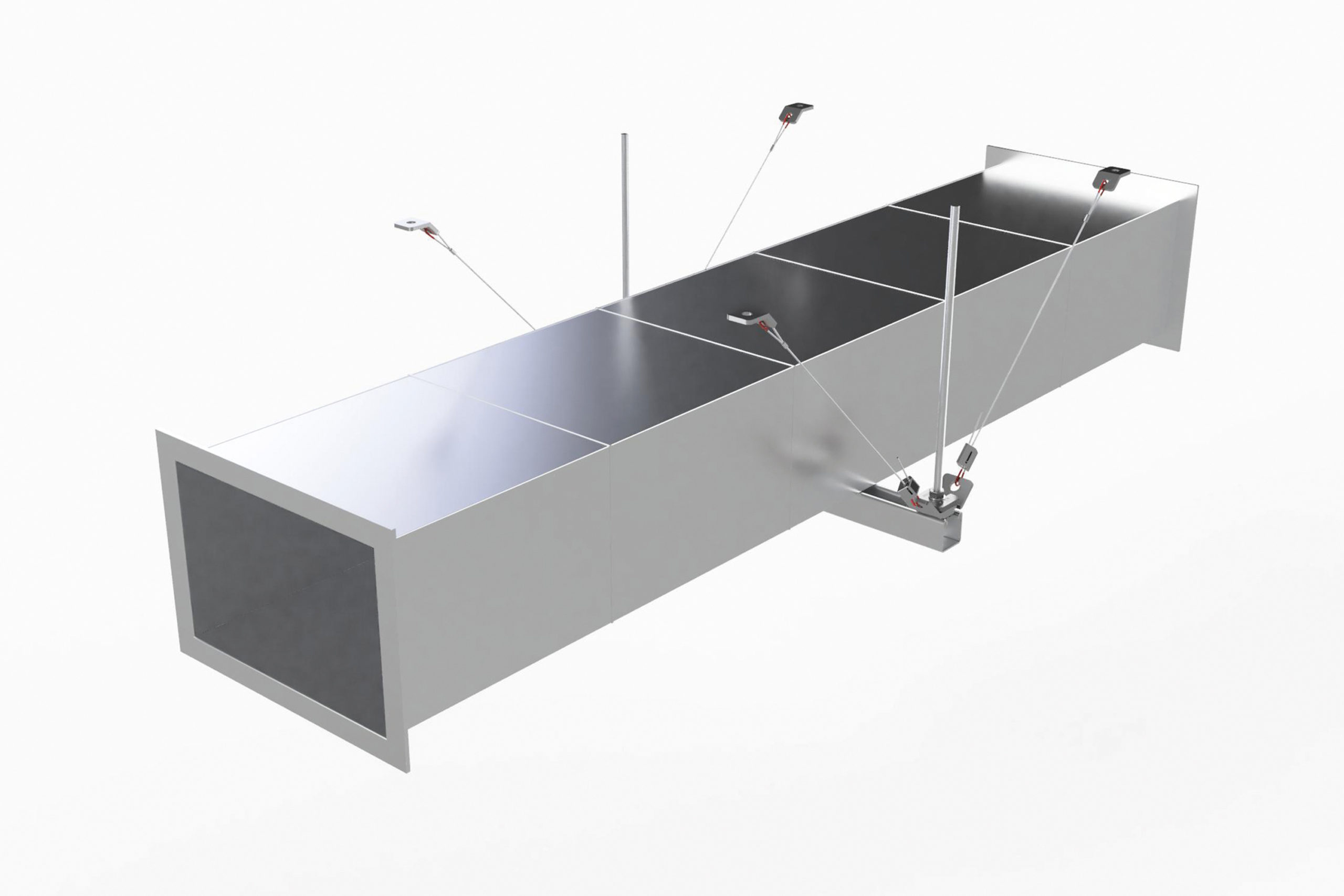

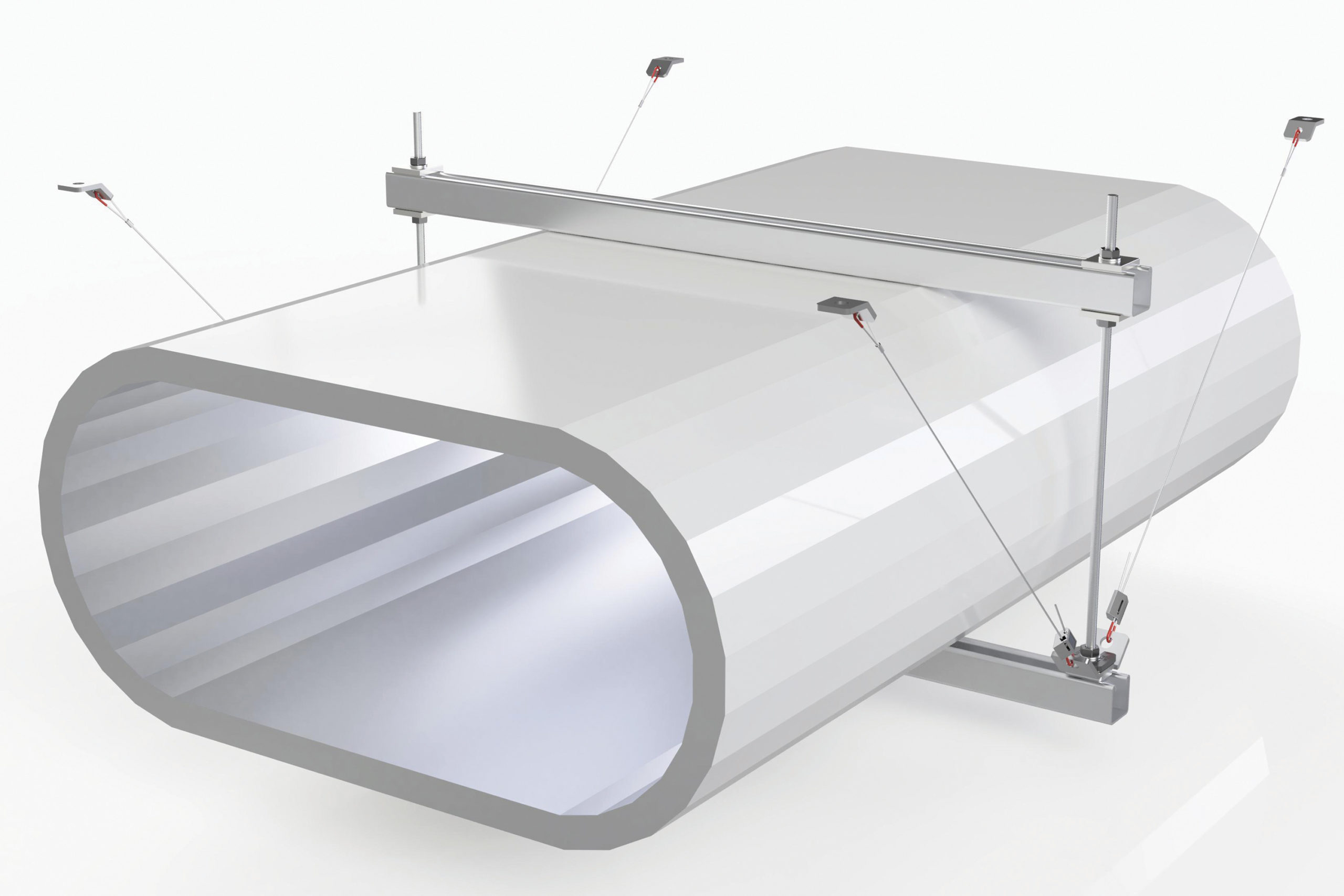

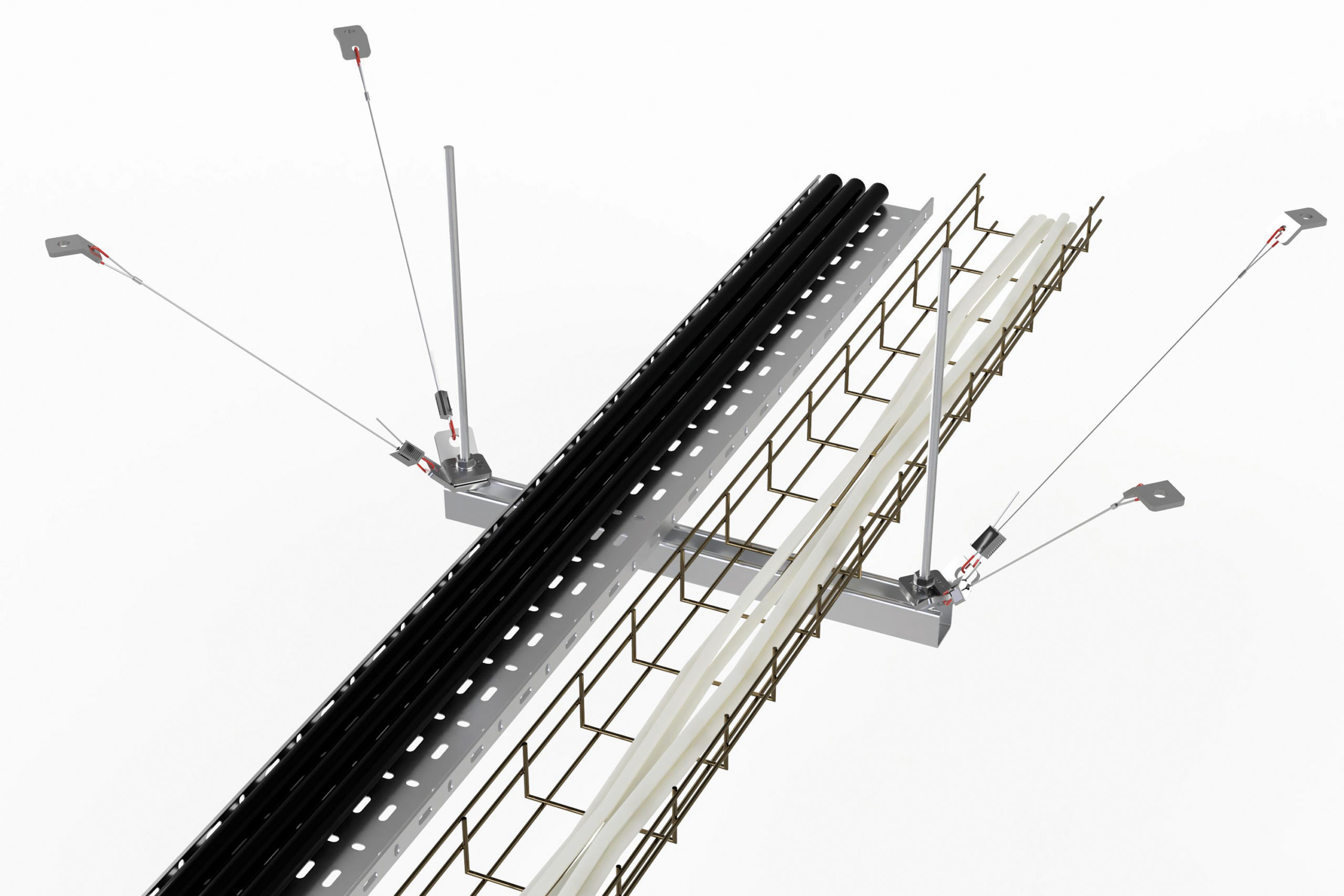

The design and installation of Zip-Clip seismic cable bracing for building services not only achieves the life-safety requirements of building codes and seismic design standards but also makes significant improvements to the functional recovery of buildings following an earthquake, by minimising seismic movement and associated damage.