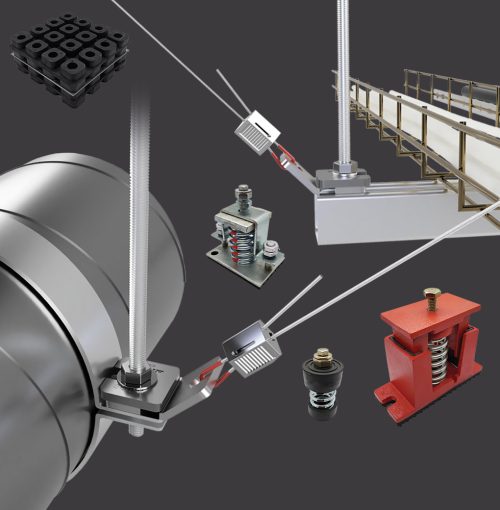

Zip-Rod

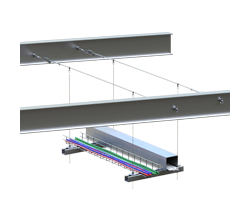

Threaded thermoplastic rods are designed to be utilised in the same way that galvanised threaded rod is used; enabling the installer to build bracketry such as trapeze brackets for supporting services. The range also consists of a number of accessories to form an attachment to a fixing point or fixture.

APPLICATIONS

- Cable management

- Ductwork systems

- Lighting track and bus bar

- Acoustic baffles and islands

- Signage

FEATURES AND BENEFITS

• Lightweight excellent chemical and corrosion resistance

• High strength

• Hygienic

• Requires “Zero” cleaning and maintenance (pool environments)

• Chemically and biologically inert

• Efficient thermal and electrical insulators

• Non-magnetic for use in MRI and CAT scan environments

Safe working loads

- 30 kg