INTRODUCTION

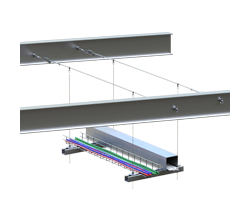

Installers of suspended signage, screens, and partitions and those installing acoustic panels frequently face wide-ranging requirements. Applications can exist in many different formats, the most popular of which are referenced in this guide.

Attention to detail, alongside safety and security, are all key elements that go into delivering the finished solution.

Differences in ceiling types, load requirements, and service connections are just a few of the critical components that must be assessed and fully addressed. The wide range of solutions provided by Zip-Clip are all purpose designed to meet exacting requirements.

WHERE CAN WIRE ROPE SUSPENSION SYSTEMS BE USED?

Zip-Clip wire rope systems can be utilised for suspension, bracing, and more, offering considerable application functionality and flexibility.

Zip-Clip systems are available with proven load-carrying capacities from 15 kg to 500 kg per wire support, plus all systems are designed with a built-in safety factor for complete peace of mind. Wire rope also allows longer drops to be installed without the need for additional couplers.

Systems are compliant with 18th Edition Amendment 2 : 2022 unless otherwise stated.

- Light to heavy-duty signage

- Acoustic ceilings, islands, or baffles

FIXING SOLUTIONS

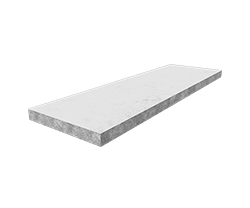

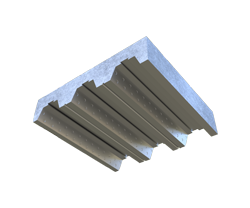

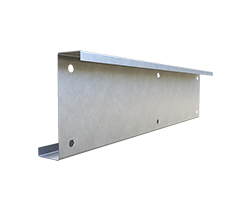

The Zip-Clip range offers a variety of suspension options to suit light, medium, and heavy-duty applications. Anchoring solutions are available for concrete, steel frame, metal-deck, and wooden structures.

Concrete anchors compliant with BS 8539:2012 (The selection and installation of post-installed anchors in concrete and masonry) can be tested on-site by CFA (Construction Fixings Association) certified technical managers. This service is available on request.

GENERAL RECOMMENDATIONS

Zip-Clip suspension systems are designed to support STATIC loads only. Dynamic and shock loads must be avoided as they can greatly increase the overall effective load of the product being suspended and therefore compromise the safe working load of the suspension. To ensure the integrity and safety of the system only Zip-Clip wire rope should be used. Some install applications, will by their nature, expose the suspension system to dynamic loads. To give increased peace of mind in this scenario Zip-Clip recommends utilizing the S-SYSTEM or above. Also, to ensure the integrity and safety of the system only Zip-Clip wire rope should be used.

- Do not exceed the safe working load (SWL) of the product.

- Do not use locking devices with a coated wire rope.

- Do not paint or apply any other coating.

- Do not lubricate.

- Do not use for lifting applications.

- Remove any frayed cable prior to inserting into locking devices.

- Do not shock load.

- Do not use for dynamic loads/installations.

- Do not overload.

- Do not mix Zip-Clip systems with other wire rope suspension manufacturers’ products.

- Do not use in corrosive environments, e.g. chlorinated environments – For specialist applications, such as corrosive environments, please contact Zip-Clip Technical Department.

Installation Factors

Installers must pay attention to the nature of the installation process. Certain installations will introduce dynamic forces onto the supports. Where this might be the case, it is advised to select heavier-duty systems.

Ball Strikes – Where this may be a potential factor, such as installations within sports halls, heavier-duty wire rope supports should be utilised to offer maximum resistance to dynamic shock loads. Zip-Clip cannot guarantee its systems against the effects of ball strikes.