Luma-Lock

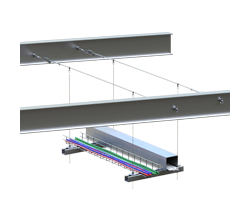

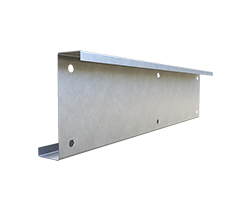

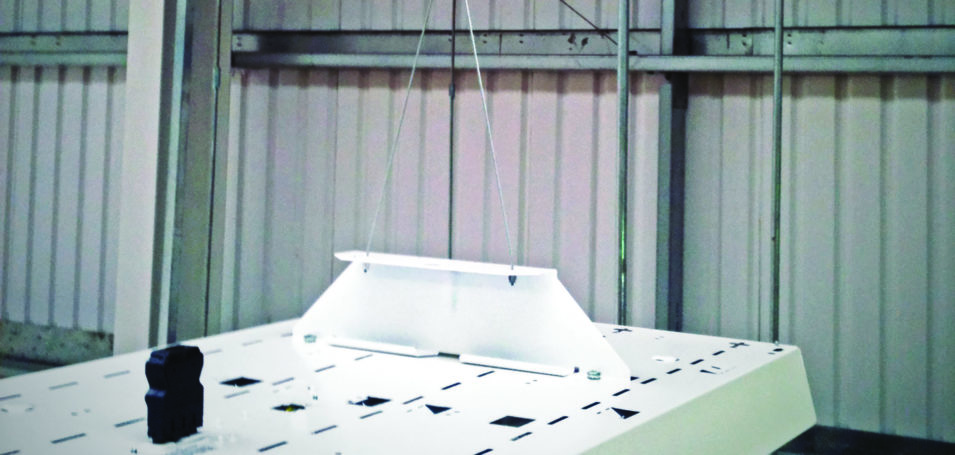

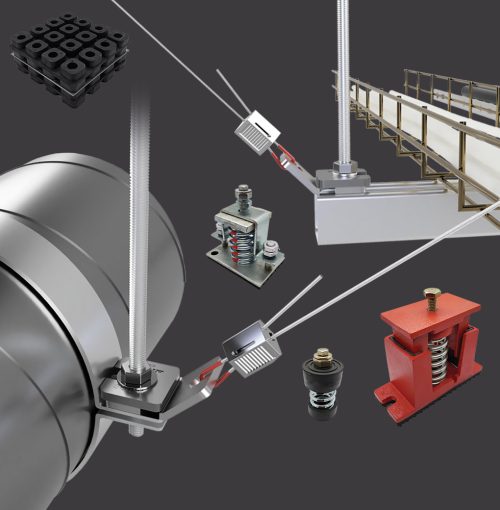

THE LUMA-LOCK SYSTEM is designed to suspend services from a single point suspension. The aim of this support is to reduce the amount of material that is used to build a support.

Luma-Locks are fitted to the intended application using toggles and then coupled to a chosen Zip-Clip vertical suspension to hang from a variety of different base materials.

THE APPLICATIONS

SUITABLE AREAS OF USE INCLUDE, BUT ARE NOT LIMITED TO:

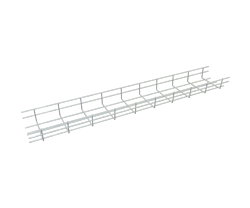

- Long cable tray runs.

- Off-shoots from the main containment.

- Light fittings.

- Radiant heat panels.

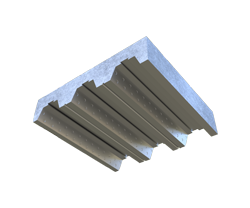

- Chilled beams.

- Acoustic boards.

- Plenum boxes.

- Long suspensions up to 10 m.

AVAILABILITY

Zip-Clip offer two different Luma-Lock systems each allocated a letter to differentiate between the available safe working loads (SWL). Each system comprises of a specific diameter of wire rope. Systems are available for spans from 50 mm up to 600 mm as standard, however, larger spans can be manufactured on request.

Safe Working Loads

- G 15 kg

- S 35 kg