INTRODUCTION

Mechanical engineers and others responsible for the design and installation of heating, ventilation, and air-conditioning (HVAC) are today facing an increasingly varied range of installation requirements, whilst working to ever-tightening regulations and industry guidelines, just like those working in many other M&E disciplines.

The design, installation, and operation of systems that heat, cool, and ventilate indoor spaces, optimizing indoor air quality by controlling temperature, humidity, and air flow in individual rooms as well as whole buildings are now in the spotlight more than ever before.

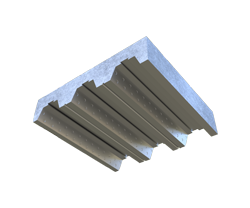

During the design phase, engineers are required to select HVAC components to be used in a project and calculate sizes and loads for pumps, pipes, ductwork, etc. Not only does the effectiveness and efficiency of the system layout have to be methodically scrutinised and optimised but like all other aspects of construction environmental implications have to be fully evaluated and this is especially true with the drive to reduce CO2 levels and the ultimate goal of achieving ‘net zero’ buildings.

HVAC SPECIFIC SUSPENSION RECOMMENDATIONS

Zip-Clip recommends that installations of all supports follow guidelines laid down in DW/144, Third Edition 2016, Specification for Sheet Metal Ductwork.

With special reference to sections titled “Arrangement of bearers and hangers” Zip-Clip recommends following industry standards with regard to the regularity of supports, as well as the exact arrangement of the support in relation to the application. In all cases, it is the responsibility of the installer to ensure that industry standards are met and followed.

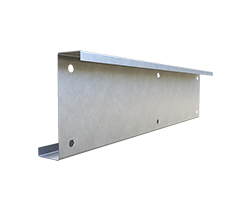

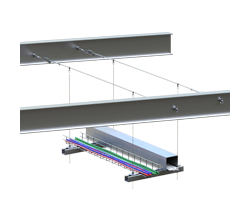

Zip-Clip wire supports are used as an alternative means of suspension to traditional threaded rod systems.

Due to the nature of HVAC installations, Zip-Clip does not recommend the use of the G-SYSTEM 15 kg SWL wire suspension for this application.

Although there are many applications within HVAC that do not call for a suspension greater than 15 kg, installation factors must be taken into account. Some HVAC applications will by nature be subjected to dynamic loads. To give peace of mind Zip-Clip recommends the S-SYSTEM and above ranges of wire suspensions.

GENERAL RECOMMENDATIONS

Zip-Clip suspension systems are designed to support STATIC loads only. Dynamic and shock loads must be avoided as they can greatly increase the overall effective load of the product being suspended and therefore compromise the safe working load of the suspension.

To ensure the integrity and safety of the system only Zip-Clip wire rope should be used.

- Do not exceed the safe working load (SWL) of the product.

- Do not use locking devices with a coated wire rope.

- Do not paint or apply any other coating.

- Do not lubricate.

- Do not use for lifting applications.

- Remove any frayed cable prior to inserting it into the locking devices.

- Do not shock load.

- Do not use for dynamic loads/installations.

- Do not overload.

- Do not mix Zip-Clip systems with other wire rope suspension manufacturers’ products.

- Do not use in corrosive environments, e.g. chlorinated environments – For specialist applications, such as corrosive environments, please contact Zip-Clip Technical Department.

INSTALLATION FACTORS

Installers must pay attention to the nature of the installation process. Certain installations will introduce dynamic forces onto the supports. Where this might be the case, it is advised to select heavier-duty systems.

Ball Strikes – Where this may be a potential factor, such as installations within sports halls, heavier-duty wire rope supports should be utilised to offer maximum resistance to dynamic shock loads. Zip-Clip cannot guarantee its systems against the effects of ball strikes.